GET A FREE QUOTE

Please call: 1300 265 887

Or submit a quote request:

Hydraulic Jacking Cylinders

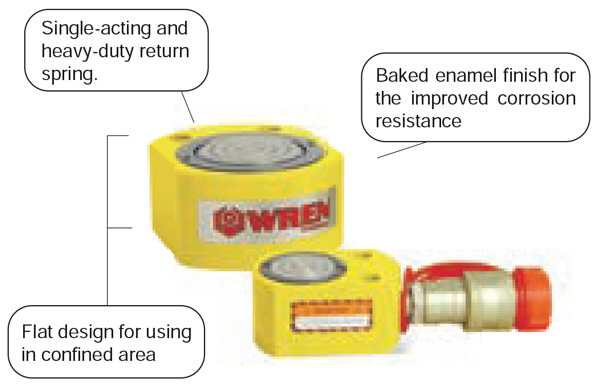

RSM series Single – Acting Low Weight Cylinder

RSM Series Selection Chart |

||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Saddle Diameter (mm) | Weight (kg) |

| 5 | 6 | Rsm50 | 32 | 59 x 42 | 7 | 4 | 26 | 1.0 |

| 10 | 11 | RSM100 | 42 | 83 x 56 | 14.5 | 16 | 38 | 1.4 |

| 20 | 11 | RSM200 | 51 | 100 x 75 | 28.2 | 31 | 50 | 3.1 |

| 30 | 13 | RSM300 | 58 | 118 x 95 | 41.8 | 54 | 63 | 4.5 |

| 50 | 16 | RSM500 | 66 | 140 x 115 | 63.6 | 101 | 70 | 6.8 |

| 75 | 16 | RSM750 | 79 | 166 x 140 | 103.8 | 166 | 63 | 11.3 |

| 100 | 16 | RSM1000 | 85 | 178 x 153 | 132.7 | 212 | 75 | 14.5 |

| 150 | 16 | RSM1500 | 100 | 216 x 191 | 201 | 321 | 112 | 26.3 |

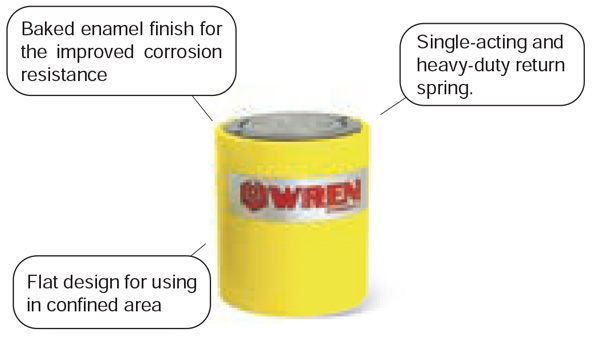

RCS series Single – Acting Low Weight Cylinder

RCS Series Selection Chart |

||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Saddle Diameter (mm) | Weight (kg) |

| 10 | 38 | RCS101 | 88 | 70 | 14.5 | 55 | 38 | 4.1 |

| 20 | 45 | RCS201 | 98 | 92 | 28.2 | 127 | 50 | 5.0 |

| 30 | 61 | RCS302 | 117 | 102 | 41.8 | 255 | 65 | 6.8 |

| 50 | 60 | RCS502 | 122 | 127 | 63.6 | 381 | 70 | 10.9 |

| 100 | 57 | RCS1002 | 141 | 167 | 132.7 | 756 | 90 | 22.7 |

| 150 | 51 | RCS1502 | 206 | 205 | 201.1 | 1025 | 138 | 42.1 |

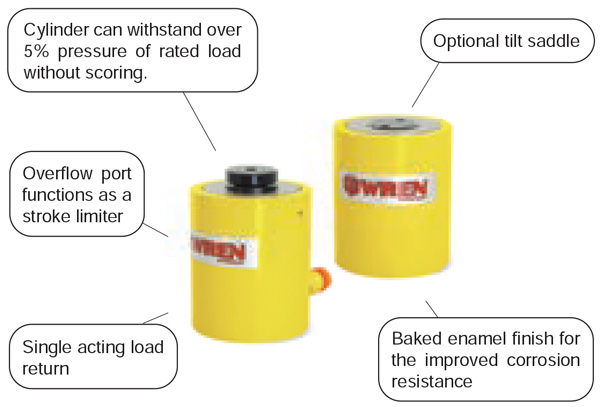

RC series Single – Acting General Purpose Cylinder

RC Series Selection Chart |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Saddle Diameter (mm) | Thread Size | Thread Length (mm) | Weight (Kg) |

| 5 | 16 | RC50 | 42 | 42 X 59 | 7 | 11 | 26 | 1 1/2″-16 | 28 | 1.1 |

| 5 | 25 | RC51 | 110 | 38 | 6.5 | 16 | 25.5 | 1 1/2″-16 | 28 | 1.1 |

| 5 | 76 | RC53 | 165 | 38 | 6.5 | 50 | 25.5 | 1 1/2″-16 | 28 | 1.5 |

| 5 | 127 | RC55 | 215 | 38 | 6.5 | 83 | 25.5 | 1 1/2″-16 | 28 | 1.9 |

| 5 | 177 | RC57 | 273 | 38 | 6.5 | 115 | 25.5 | 1 1/2″-16 | 28 | 2.4 |

| 5 | 232 | RC59 | 323 | 38 | 6.5 | 151 | 25.5 | 1 1/2″-16 | 28 | 2.8 |

| 10 | 26 | RC101 | 89 | 57 | 14.5 | 38 | 35 | 2 1/4″-14 | 27 | 1.8 |

| 10 | 54 | RC102 | 121 | 57 | 14.5 | 78 | 35 | 2 1/4″-14 | 27 | 2.3 |

| 10 | 105 | RC104 | 171 | 57 | 14.5 | 152 | 35 | 2 1/4″-14 | 27 | 3.3 |

| 10 | 156 | RC106 | 247 | 57 | 14.5 | 226 | 35 | 2 1/4″-14 | 27 | 4.4 |

| 10 | 203 | RC108 | 298 | 57 | 14.5 | 294 | 35 | 2 1/4″-14 | 27 | 5.4 |

| 10 | 257 | RC1010 | 349 | 57 | 14.5 | 373 | 35 | 2 1/4″-14 | 27 | 6.4 |

| 10 | 304 | RC1012 | 400 | 57 | 14.5 | 441 | 35 | 2 1/4″-14 | 27 | 6.8 |

| 10 | 356 | RC1014 | 450 | 57 | 14.5 | 516 | 35 | 2 1/4″-14 | 27 | 8.2 |

| 15 | 25 | RC151 | 124 | 70 | 19.6 | 49 | 38 | 2 3/4″-16 | 30 | 3.3 |

| 15 | 51 | RC152 | 149 | 70 | 19.6 | 100 | 38 | 2 3/4″-16 | 30 | 4.1 |

| 15 | 101 | RC154 | 200 | 70 | 19.6 | 198 | 38 | 2 3/4″-16 | 30 | 5.0 |

| 15 | 152 | RC156 | 271 | 70 | 19.6 | 298 | 38 | 2 3/4″-16 | 30 | 6.8 |

| 15 | 203 | RC158 | 322 | 70 | 19.6 | 398 | 38 | 2 3/4″-16 | 30 | 8.2 |

| 15 | 254 | RC1510A | 373 | 70 | 19.6 | 498 | 38 | 2 3/4″-16 | 30 | 9.5 |

| 15 | 305 | RC1512A | 423 | 70 | 19.6 | 598 | 38 | 2 3/4″-16 | 30 | 10.9 |

| 15 | 356 | RC1514A | 474 | 70 | 19.6 | 697 | 38 | 2 3/4″-16 | 30 | 11.8 |

| 25 | 26 | RC251 | 139 | 85 | 33.2 | 86 | 50 | 3 5/16″-12 | 49 | 5.9 |

| 25 | 50 | RC252 | 165 | 85 | 33.2 | 166 | 50 | 3 5/16″-12 | 49 | 6.4 |

| 25 | 102 | RC254 | 215 | 85 | 33.2 | 339 | 50 | 3 5/16″-12 | 49 | 8.2 |

| 25 | 158 | RC256 | 273 | 85 | 33.2 | 525 | 50 | 3 5/16″-12 | 49 | 10.0 |

| 25 | 210 | RC258 | 323 | 85 | 33.2 | 697 | 50 | 3 5/16″-12 | 49 | 12.2 |

| 25 | 261 | RC2510A | 374 | 85 | 33.2 | 867 | 50 | 3 5/16″-12 | 49 | 14.1 |

| 25 | 311 | RC2512A | 425 | 85 | 33.2 | 1033 | 50 | 3 5/16″-12 | 49 | 16.3 |

| 25 | 362 | RC2514 | 476 | 85 | 33.2 | 1202 | 50 | 3 5/16″-12 | 49 | 17.7 |

| 30 | 209 | RC308 | 387 | 102 | 44.2 | 923 | 50 | 18.1 | ||

| 50 | 51 | RC502 | 176 | 127 | 70.8 | 361 | 71 | 5″-12 | 55 | 15.0 |

| 50 | 101 | RC504 | 227 | 127 | 70.8 | 715 | 71 | 5″-12 | 55 | 19.1 |

| 50 | 159 | RC506 | 282 | 127 | 70.8 | 1125 | 71 | 5″-12 | 55 | 23.1 |

| 50 | 337 | RC5013 | 460 | 127 | 70.8 | 2386 | 71 | 5″-12 | 55 | 37.6 |

| 75 | 156 | RC756 | 285 | 147 | 103.8 | 1619 | 71 | 5 3/4″-12 | 44 | 29.5 |

| 75 | 333 | RC7513A | 492 | 147 | 103.8 | 3456 | 71 | 5 3/4″-12 | 44 | 59.0 |

| 100 | 168 | RC1006 | 357 | 177 | 132.7 | 2229 | 71 | 6 7/8″-12 | 44 | 59.0 |

| 100 | 260 | RC10010 | 449 | 177 | 133.3 | 3450 | 71 | 6 7/8″-12 | 44 | 72.6 |

RCH series Single – Acting Hollow Plunger Cylinder

RCH Series Selection Chart |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Plunger Diameter (mm) | Hollow Diameter (mm) | Weight (kg) |

| 12 | 8 | RCH120 | 55 | 69 | 17.9 | 14 | 35 | 19 | 1.5 |

| 12 | 42 | RCH121 | 120 | 69 | 17.9 | 75 | 35 | 19 | 2.8 |

| 12 | 76 | RCH123 | 184 | 69 | 17.9 | 136 | 35 | 19 | 4.4 |

| 20 | 50 | RCH202 | 162 | 99 | 30.5 | 152 | 55 | 26.9 | 7.7 |

| 20 | 155 | RCH206 | 306 | 99 | 30.5 | 473 | 55 | 28 | 14.1 |

| 30 | 64 | RCH302 | 179 | 115 | 47.7 | 305 | 63 | 34 | 10.9 |

| 30 | 155 | RCH306 | 331 | 115 | 47.7 | 739 | 63.5 | 34 | 21.8 |

| 60 | 77 | RCH603 | 248 | 160 | 84.2 | 648 | 92 | 53 | 28.1 |

| 60 | 152 | RCH606 | 325 | 160 | 84.2 | 1280 | 92 | 53 | 35.4 |

| 100 | 76 | RCH1003 | 254 | 212 | 135.3 | 1028 | 127.0 | 78 | 63.0 |

RRH series Double-Acting Hollow Plunger Cylinder

RRH Series Selection Chart |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Plunger Diameter (mm) | Hollow Diameter (mm) | Weight (kg) | |||

| Push | Pull | Push | Pull | Push | Pull | |||||||

| 34 | 23 | 178 | RRH307A | 331 | 115 | 47.7 | 32.4 | 849 | 576 | 63 | 34 | 21 |

| 30 | 23 | 258 | RRH3010A | 431 | 115 | 47.7 | 32.4 | 1230 | 836 | 63 | 34 | 27 |

| 60 | 42 | 89 | RRH603A | 248 | 160 | 84.2 | 56.2 | 749 | 500 | 95 | 53 | 28 |

| 60 | 42 | 165 | RRH606A | 324 | 160 | 84.2 | 56.2 | 1389 | 927 | 95 | 53 | 35 |

| 60 | 42 | 257 | RRH6010 | 438 | 160 | 84.2 | 56.2 | 2164 | 1444 | 95 | 53 | 45 |

| 100 | 68 | 38 | RRH1001A | 166 | 212 | 135.2 | 87.1 | 513 | 331 | 127 | 79 | 33 |

| 100 | 68 | 76 | RRH1003A | 255 | 212 | 135.2 | 87 | 1027 | 661 | 127 | 78 | 61 |

| 100 | 68 | 153 | RRH1006A | 343 | 212 | 135.2 | 87 | 2068 | 1331 | 127 | 78 | 79 |

| 100 | 68 | 253 | RRH10010A | 443 | 212 | 135.2 | 87 | 3420 | 2201 | 127.0 | 78 | 106 |

| 150 | 75 | 200 | RRH1508 | 349 | 247 | 205 | 106.8 | 4100 | 2136 | 152 | 78 | 111 |

CLS series Single – Acting High Tonnage Cylinder

CLS Series Selection Chart |

||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Saddle Diameter (mm) | Weight (kg) |

| 50 | 50 | CLS502A | 128 | 125 | 70.9 | 355 | 71 | 4 |

| 50 | 100 | CLS504A | 178 | 125 | 70.9 | 709 | 71 | 18 |

| 50 | 150 | CLS506 | 228 | 125 | 70.9 | 1064 | 71 | 23 |

| 50 | 200 | CLS508A | 278 | 125 | 70.9 | 1418 | 71 | 28 |

| 50 | 250 | CLS5010A | 328 | 125 | 70.9 | 1773 | 71 | 33 |

| 50 | 300 | CLS5012A | 378 | 125 | 70.9 | 2127 | 71 | 38 |

| 100 | 50 | CLS1002A | 143 | 164 | 132.7 | 664 | 71 | 24 |

| 100 | 100 | CLS1004 | 193 | 164 | 132.7 | 1327 | 71 | 32 |

| 100 | 150 | CLS1006 | 243 | 164 | 132.7 | 1991 | 71 | 40 |

| 100 | 200 | CLS1008A | 293 | 164 | 132.7 | 2654 | 71 | 49 |

| 100 | 250 | CLS10010 | 343 | 164 | 132.7 | 3318 | 71 | 58 |

| 100 | 300 | CLS10012 | 393 | 164 | 132.7 | 3981 | 71 | 66 |

| 150 | 50 | CLS1502 | 165 | 209 | 201 | 1005 | 130 | 43 |

| 150 | 100 | CLS1504 | 215 | 209 | 201 | 2010 | 130 | 55 |

| 150 | 150 | CLS1506 | 265 | 209 | 201 | 3015 | 130 | 69 |

| 150 | 200 | CLS1508 | 315 | 209 | 201 | 4020 | 130 | 82 |

| 150 | 250 | CLS15010 | 365 | 209 | 201 | 5025 | 130 | 95 |

| 150 | 300 | CLS15012 | 415 | 209 | 201 | 6030 | 130 | 108 |

| 200 | 50 | CLS2002 | 193 | 235 | 265.9 | 1330 | 130 | 66 |

| 200 | 150 | CLS2006 | 293 | 235 | 265.9 | 3989 | 130 | 101 |

| 200 | 250 | CLS20010A | 393 | 235 | 265.9 | 6648 | 130 | 136 |

| 250 | 50 | CLS2502 | 193 | 275 | 366.4 | 1832 | 150 | 90 |

| 250 | 150 | CLS2506 | 293 | 275 | 366.4 | 5496 | 150 | 137 |

| 250 | 250 | CLS25010 | 393 | 275 | 366.4 | 9160 | 150 | 184 |

| 300 | 50 | CLS3002 | 235 | 310 | 456.2 | 2281 | 139 | 137 |

| 300 | 150 | CLS3006 | 335 | 310 | 456.2 | 6843 | 139 | 198 |

| 300 | 250 | CLS30010 | 435 | 310 | 456.2 | 11405 | 139 | 258 |

| 400 | 50 | CLS4002 | 265 | 350 | 559.9 | 2800 | 159 | 200 |

| 400 | 150 | CLS4006 | 365 | 350 | 559.9 | 8399 | 159 | 275 |

| 400 | 250 | CLS40010 | 465 | 350 | 559.9 | 13998 | 159 | 352 |

| 500 | 50 | CLS5002 | 295 | 400 | 730.6 | 3656 | 228 | 289 |

| 500 | 150 | CLS5006 | 395 | 400 | 730.6 | 10967 | 228 | 390 |

| 500 | 250 | CLS50010 | 495 | 400 | 730.6 | 18278 | 228 | 489 |

| 600 | 50 | CLS6002 | 310 | 430 | 855.3 | 4277 | 194 | 350 |

| 600 | 150 | CLS6006 | 410 | 430 | 855.3 | 12830 | 194 | 465 |

| 600 | 250 | CLS60010 | 510 | 430 | 855.3 | 21383 | 194 | 582 |

| 800 | 50 | CLS8002 | 355 | 505 | 1176.3 | 5882 | 224 | 549 |

| 800 | 150 | CLS8006 | 455 | 505 | 1176.3 | 17645 | 224 | 709 |

| 800 | 250 | CLS80010 | 555 | 505 | 1176.3 | 29408 | 224 | 870 |

| 1000 | 50 | CLS10002 | 385 | 560 | 1465.7 | 7329 | 360 | 729 |

| 1000 | 150 | CLS10006 | 485 | 560 | 1465.7 | 21986 | 360 | 921 |

| 1000 | 250 | CLS100010 | 585 | 560 | 1465.7 | 36643 | 360 | 1113 |

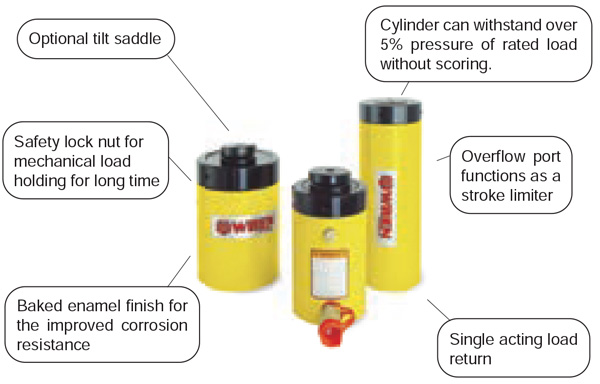

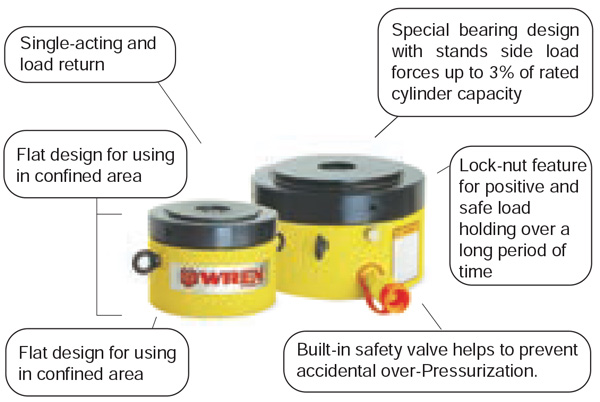

CLL series Single – Acting Lock Nut Cylinder

CLL Series Selection Chart |

||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Saddle Diameter (mm) | Weight (kg) |

| 50 | 50 | CLL502 | 164 | 125 | 70.9 | 355 | 71 | 15 |

| 50 | 100 | CLL504 | 214 | 125 | 70.9 | 709 | 71 | 20 |

| 50 | 150 | CLL506 | 264 | 125 | 70.9 | 1064 | 71 | 25 |

| 50 | 200 | CLL508 | 314 | 125 | 70.9 | 1418 | 71 | 30 |

| 50 | 250 | CLL5010 | 364 | 125 | 70.9 | 1773 | 71 | 35 |

| 50 | 300 | CLL5012 | 414 | 125 | 70.9 | 2127 | 71 | 40 |

| 100 | 50 | CLL1002 | 187 | 165 | 132.7 | 664 | 71 | 30 |

| 100 | 100 | CLL1004 | 237 | 165 | 132.7 | 1327 | 71 | 39 |

| 100 | 150 | CLL1006 | 287 | 165 | 132.7 | 1991 | 71 | 48 |

| 100 | 200 | CLL1008 | 337 | 165 | 132.7 | 2654 | 71 | 56 |

| 100 | 250 | CLL10010 | 387 | 165 | 132.7 | 3318 | 71 | 64 |

| 100 | 300 | CLL10012 | 437 | 165 | 132.7 | 3981 | 71 | 73 |

| 150 | 50 | CLL1502 | 209 | 205 | 201 | 1005 | 130 | 53 |

| 150 | 100 | CLL1504 | 259 | 205 | 201 | 2010 | 130 | 66 |

| 150 | 150 | CLL1506 | 309 | 205 | 201 | 3015 | 130 | 78 |

| 150 | 200 | CLL1508 | 359 | 205 | 201 | 4020 | 130 | 92 |

| 150 | 250 | CLL15010 | 409 | 205 | 201 | 5025 | 130 | 104 |

| 150 | 300 | CLL15012 | 459 | 205 | 201 | 6030 | 130 | 117 |

| 200 | 50 | CLL2002 | 243 | 235 | 265.6 | 1330 | 130 | 83 |

| 200 | 150 | CLL2006 | 343 | 235 | 265.6 | 3989 | 130 | 117 |

| 200 | 250 | CLL20010 | 443 | 235 | 265.6 | 6648 | 130 | 152 |

| 250 | 50 | CLL2502 | 249 | 275 | 366.4 | 1832 | 150 | 116 |

| 250 | 150 | CLL2506 | 349 | 275 | 366.4 | 5496 | 150 | 162 |

| 250 | 250 | CLL25010 | 449 | 275 | 366.4 | 9160 | 150 | 210 |

| 300 | 50 | CLL3002 | 295 | 310 | 456.2 | 2281 | 139 | 173 |

| 300 | 150 | CLL3006 | 395 | 310 | 456.2 | 6843 | 139 | 233 |

| 300 | 250 | CLL30010 | 495 | 310 | 456.2 | 11405 | 139 | 293 |

| 400 | 50 | CLL4002 | 335 | 350 | 559.9 | 2800 | 159 | 250 |

| 400 | 150 | CLL4006 | 435 | 350 | 559.9 | 8399 | 159 | 327 |

| 400 | 250 | CLL40010 | 535 | 350 | 559.9 | 13998 | 159 | 402 |

| 500 | 50 | CLL5002 | 375 | 400 | 730.6 | 3656 | 228 | 367 |

| 500 | 150 | CLL5006 | 475 | 400 | 730.6 | 10967 | 228 | 466 |

| 500 | 250 | CLL50010 | 575 | 400 | 730.6 | 18278 | 228 | 567 |

| 600 | 50 | CLL6002 | 395 | 430 | 855.3 | 4277 | 194 | 446 |

| 600 | 150 | CLL6006 | 495 | 430 | 855.3 | 12830 | 194 | 562 |

| 600 | 250 | CLL60010 | 595 | 430 | 855.3 | 21383 | 194 | 679 |

| 800 | 50 | CLL8002 | 455 | 505 | 1176.9 | 5882 | 224 | 709 |

| 800 | 150 | CLL8006 | 555 | 505 | 1176.9 | 17645 | 224 | 870 |

| 800 | 250 | CLL80010 | 655 | 505 | 1176.9 | 29408 | 224 | 1029 |

| 1000 | 50 | CLL10002 | 495 | 560 | 1466.4 | 7329 | 360 | 949 |

| 1000 | 150 | CLL10006 | 595 | 560 | 1466.4 | 21986 | 360 | 1141 |

| 1000 | 250 | CLL100010 | 695 | 560 | 1466.4 | 36643 | 360 | 1333 |

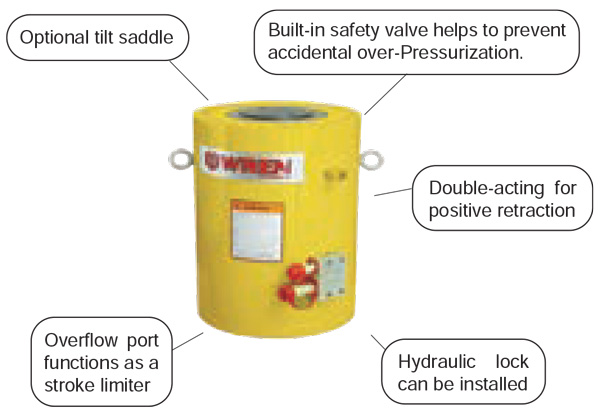

CLRG series Double – Acting High Tonnage Cylinder

CLRG Series Selection Chart |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Saddle Diameter (mm) | Weight (kg) | |||

| Push | Pull | Push | Pull | Push | Pull | ||||||

| 10 | 4.1 | 254 | CLRG1010 | 409 | 76 | 14.5 | 5.9 | 368 | 149 | 33 | 12 |

| 10 | 4.1 | 305 | CLRG1012 | 457 | 76 | 14.5 | 5.9 | 442 | 180 | 33 | 14 |

| 50 | 22.6 | 150 | CLRG506 | 325 | 127 | 70.8 | 32.3 | 1062 | 484 | 70 | 30 |

| 50 | 22.6 | 300 | CLRG5012 | 475 | 127 | 70.8 | 32.3 | 2124 | 969 | 70 | 52 |

| 100 | 44 | 50 | CLRG1002 | 182 | 188 | 132.7 | 61.9 | 664 | 310 | 95 | 27 |

| 100 | 44 | 100 | CLRG1004 | 232 | 188 | 132.7 | 61.9 | 1327 | 619 | 95 | 33 |

| 100 | 44 | 150 | CLRG1006 | 282 | 188 | 132.7 | 61.9 | 1991 | 929 | 95 | 37 |

| 100 | 44 | 200 | CLRG1008 | 332 | 188 | 132.7 | 61.9 | 2654 | 1238 | 95 | 44 |

| 100 | 44 | 250 | CLRG10010 | 382 | 188 | 132.7 | 61.9 | 3318 | 1548 | 95 | 50 |

| 100 | 44 | 300 | CLRG10012 | 432 | 188 | 132.7 | 61.9 | 3981 | 1857 | 95 | 57 |

| 150 | 67.9 | 50 | CLRG1502 | 196 | 216 | 201 | 97 | 1005 | 485 | 115 | 47 |

| 150 | 67.9 | 100 | CLRG1504 | 246 | 216 | 201 | 97 | 2010 | 970 | 115 | 57 |

| 150 | 67.9 | 150 | CLRG1506 | 296 | 216 | 201 | 97 | 3015 | 1455 | 115 | 67 |

| 150 | 67.9 | 200 | CLRG1508 | 346 | 216 | 201 | 97 | 4020 | 1940 | 115 | 77 |

| 150 | 67.9 | 250 | CLRG15010 | 396 | 216 | 201 | 97 | 5025 | 2425 | 115 | 87 |

| 150 | 67.9 | 300 | CLRG15012 | 446 | 216 | 201 | 97 | 6030 | 2910 | 115 | 97 |

| 200 | 93 | 50 | CLRG2002 | 235 | 242 | 265.9 | 133.1 | 1329 | 665 | 130 | 67 |

| 200 | 93 | 150 | CLRG2006 | 335 | 242 | 265.9 | 133.1 | 3988 | 1996 | 130 | 92 |

| 200 | 93 | 250 | CLRG20010 | 435 | 242 | 265.9 | 133.1 | 6647 | 3327 | 130 | 117 |

| 250 | 107 | 50 | CLRG2502 | 236 | 288 | 366.4 | 152.6 | 1832 | 763 | 165 | 105 |

| 250 | 107 | 150 | CLRG2506 | 336 | 288 | 366.4 | 152.6 | 5496 | 2289 | 165 | 141 |

| 250 | 107 | 250 | CLRG25010 | 436 | 288 | 366.4 | 152.6 | 9160 | 3815 | 165 | 176 |

| 300 | 121 | 50 | CLRG3002 | 350 | 325 | 456.2 | 172.6 | 2281 | 863 | 190 | 204 |

| 300 | 121 | 150 | CLRG3006 | 412 | 325 | 456.2 | 172.6 | 6843 | 2589 | 190 | 252 |

| 300 | 121 | 250 | CLRG30010 | 512 | 325 | 456.2 | 172.6 | 11405 | 4315 | 190 | 299 |

| 400 | 138 | 50 | CLRG4002 | 370 | 367 | 559.9 | 196.8 | 2799 | 984 | 215 | 281 |

| 400 | 138 | 150 | CLRG40060 | 470 | 367 | 559.9 | 196.8 | 8399 | 2952 | 215 | 342 |

| 400 | 138 | 250 | CLRG40010 | 570 | 367 | 559.9 | 196.8 | 13998 | 4920 | 215 | 405 |

| 500 | 168 | 50 | CLRG5002 | 400 | 405 | 730.6 | 239.7 | 3653 | 1198 | 250 | 411 |

| 500 | 168 | 150 | CLRG5006 | 500 | 405 | 730.6 | 239.7 | 10959 | 3595 | 250 | 493 |

| 500 | 168 | 250 | CLRG50010 | 600 | 405 | 730.6 | 239.7 | 18265 | 5992 | 250 | 575 |

| 600 | 207 | 50 | CLRG6002 | 445 | 450 | 855.3 | 295.4 | 4277 | 1477 | 267 | 494 |

| 600 | 207 | 150 | CLRG6006 | 545 | 450 | 855.3 | 295.4 | 12830 | 4431 | 267 | 586 |

| 600 | 207 | 250 | CLRG60010 | 645 | 450 | 855.3 | 295.4 | 21383 | 7385 | 267 | 678 |

| 800 | 252 | 50 | CLRG8002 | 695 | 515 | 1164 | 360 | 5820 | 1800 | 320 | 759 |

| 800 | 252 | 150 | CLRG8006 | 595 | 515 | 1164 | 360 | 17460 | 5400 | 320 | 885 |

| 800 | 252 | 250 | CLRG80010 | 695 | 515 | 1164 | 360 | 29100 | 9000 | 320 | 1019 |

| 1000 | 380 | 50 | CLRG10002 | 535 | 580 | 1465.7 | 541.7 | 7328 | 2708 | 342 | 1012 |

| 1000 | 380 | 150 | CLRG10006 | 635 | 580 | 1465.7 | 541.7 | 21985 | 8125 | 342 | 1168 |

| 1000 | 380 | 250 | CLRG100010 | 735 | 580 | 1465.7 | 541.7 | 36418 | 13543 | 342 | 1325 |

CLP series Single – Acting Pancake Lock Nut Cylinder

CLP Series Selection Chart |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Min Height (mm) | Outside Diameter (mm) | Effective Area (cm2) | Oil Capacity (cm3) | Saddle Diameter (mm) | Weight (kg) | |||

| 60 | 50 | CLP602 | 125 | 140 | 86.6 | 432 | 96 | 15 | |||

| 100 | 50 | CLP1002 | 137 | 175 | 143.1 | 716 | 126 | 26 | |||

| 160 | 45 | CLP1602 | 148 | 220 | 227 | 1022 | 160 | 44 | |||

| 200 | 45 | CLP2002 | 155 | 245 | 283.5 | 1276 | 180 | 57 | |||

| 260 | 45 | CLP2502 | 159 | 275 | 366.4 | 1649 | 200 | 74 | |||

| 400 | 45 | CLP4002 | 178 | 350 | 559.9 | 2519 | 250 | 134 | |||

| 520 | 45 | CLP5002 | 192 | 400 | 730.6 | 3287 | 290 | 189 | |||

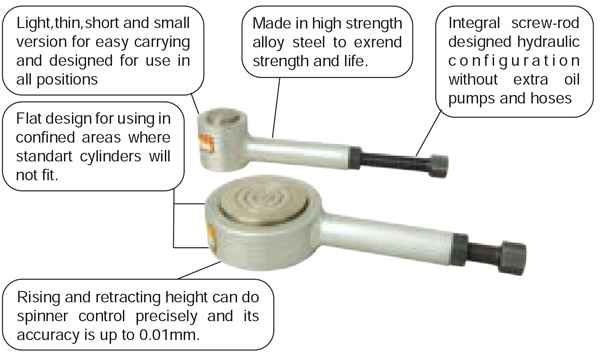

SMC series Mechanical Cylinder

SMC Series Selection Chart |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (Ton) | Stroke (mm) | Model | Effective Area (mm) | Coll. Height (mm) | Ext. Hight (mm) | Outside Diameter (mm) | Max Length (mm) | Min Length (mm) | Weight (Kg) | ||

| 5 | 25 | SMC0525 | 8.02 | 52 | 77 | 52 | 279 | 199 | 1.5 | ||

| 10 | 25 | SMC1025 | 13.85 | 54 | 79 | 62 | 351 | 240 | 2.2 | ||

| 20 | 5 | SMC2005 | 28.27 | 35 | 40 | 84 | 295 | 224 | 1.9 | ||

| 30 | 5 | SMC3005 | 38.49 | 36 | 41 | 95 | 323 | 243 | 2.3 | ||

| 50 | 5 | SMC5005 | 66.48 | 40 | 45 | 120 | 410 | 299 | 3.7 | ||

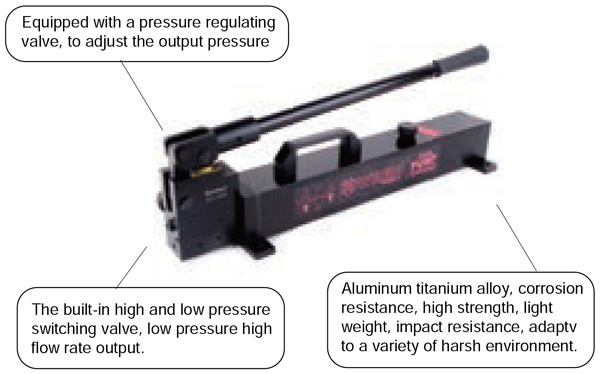

P series Hydraulic Hand Pump(700~1600Bar)

P Series Hand Pump Selection Chart |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Preasure Mpa | One Stroke Oil mL | Full Tank Oil | Available Oil | Handle Force | Size mm | Oil interface | Gauge inferface | Weight kg | ||||

| Low | Hi | Low | Hi | L | L | N | A | B | C | ||||

| P392 | 2.5 | 70 | 32 | 2.5 | 1.67 | 1.44 | 300 | 578 | 120.0 | 160 | 3/8″ NPT | 1/4″ NPT | 6.3 |

| P80 | 2.5 | 70 | 32 | 2.5 | 2.25 | 1.98 | 300 | 578 | 120.0 | 161 | 3/8″ NPT | 1/4″ NPT | 8 |

| P160 | 2.5 | 70 | 32 | 2.5 | 3.58 | 3.24 | 300 | 578 | 140.0 | 180 | 3/8″ NPT | 1/4″ NPT | 10 |

| 16P392 | 1.5 | 160 | 32 | 2.5 | 1.67 | 1.44 | 350 | 620 | 120.0 | 161 | 1/4″ BSP | 1/2″ BSP | 6.5 |

| 16P80 | 1.5 | 160 | 32 | 2.5 | 2.25 | 1.98 | 350 | 620 | 120.0 | 161 | 1/4″ BSP | 1/2″ BSP | 8.5 |

| 16P160 | 1.5 | 160 | 32 | 2.5 | 3.58 | 3.24 | 350 | 620 | 140.0 | 181 | 1/4″ BSP | 1/2″ BSP | 10.5 |

Please Call us for assistance

1300 265 887

(1300 BOLTUP)

info@torquewarehouse.com.au

Or please leave a message with your details and we will promptly be in touch.